Hi,

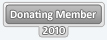

I purchased a 3/8in drive torque wrench (6.8 - 108.5 Nm) from Bunnings after I read several posts on here that Kincrome were a good brand. I got it specifically for using with the Nm scale as the workshop manual has everything in Nm.

https://www.bunnings.com.au/kincrome-...tw80f_p6100366

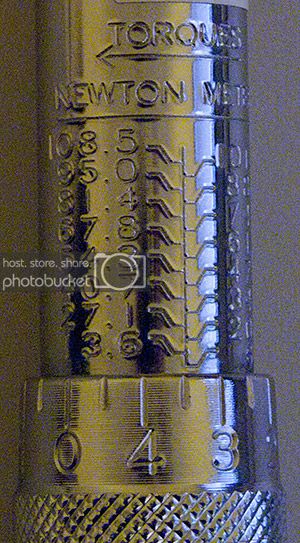

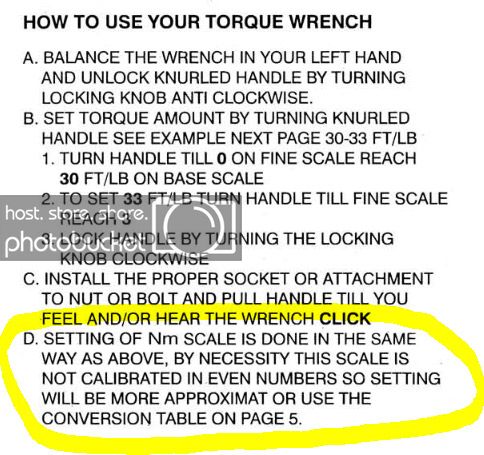

After getting it home a couldn't get my head round how to actually set the exact Nm value so something like 18 which is used on a few bolts on the intake Manifold. I read the instructions, watched youtube videos and still no luck. I can work out how to use the Ft-lb scale on the other side no problem but I don't want to have to calculate in my head the conversion between Nm - Ft-lb.

Here's the link to the pdf instructions on the kincrome site.

https://www.kincrome.com.au/documents%5CMTW80F_1.pdf

I'm positive the example value of 26.77Nm is a misprint because it doesn't add up correctly

Also the fine scale has 0 1 2 3 4 0 1 2 3 4 which is odd as all the other torque wrench's online are 1 2 3 4 5 6 7 8 9 10

I'm not a total plank as yesterday I took it back to Bunnings and asked two guys in the Tools section if they could explain how it works. Both agreed it was pretty odd and the best way would be to convert to Ft-lb. One said he would ask the rep next time he's in.

They said I can return it for a refund but the only other tool around that price is the ToolPro Torque Wrench - 3/8" Drive from Supercheapauto

Has anyone else succeeded in understanding the instructions?

Cheers,

Andrew

Reply With Quote

Reply With Quote

. At least the platinum's last for ages so you won't need to do it often. On that subject, while it's all off is a good time to replace rear valve cover and plug tube seals. There's a bunch of topics and posts on the subject on this site that are worth reading if this is something you'll be doing.

. At least the platinum's last for ages so you won't need to do it often. On that subject, while it's all off is a good time to replace rear valve cover and plug tube seals. There's a bunch of topics and posts on the subject on this site that are worth reading if this is something you'll be doing.